The solar industry is constantly advancing and adapting to its source, the sun. Today technology can track the sun with solar tracking systems. In Texas, solar tracking is easier than tracking your vehicle in the parking lot of a packed HEB grocery store.

A solar tracking array can optimize energy production. That’s right, optimize energy production. A well-known solar tracking and racking systems manufacture are Sun Action Trackers. The company was established in 2014 and is headquartered in San Antonio, TX.

Since inception, SAT is one of the New Energy Economy Consortium Partners of CPS Energy. “Sun Action Trackers helped deploy over 500MW of Tracking Technology for various CPS projects throughout Texas,” said Israel Roman, Director Project Execution with Sun Action Trackers.

A few years ago, CPS Energy committed to providing 400 MW of renewable power, known as the “Alamo Projects”. With plans to construct seven different Alamo Project locations, the development of the project was through a public-private partnership with OCI Solar Power, a parent company of SAT.

“Sun Action Tracking Systems use patented real-time sensors to capture the highest point of irradiance of the sun moving throughout the day, optimizing energy production,” explained Roman.

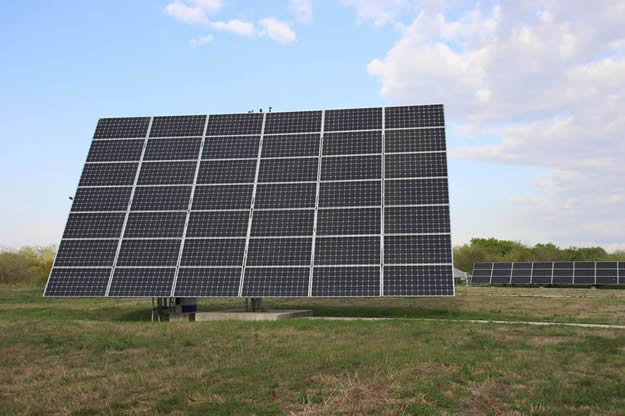

According to the CPS Energy Newsroom website, in an article titled “ConEdison Development joins CPS Energy to dedicate Alamo 5” from the year 2016, “Because of its dual-axis trackers, Alamo 5 generates power with high efficiency.

Such trackers allow for optimum solar energy output because of their ability to follow the sun both vertically and horizontally. The dual-axis trackers, which utilize a patented “solar-sensing” technology to capture maximum solar resource, were produced by Sun Action Trackers, a San Antonio-based manufacturer of solar tracking and racking systems.”

Solar tracking popularity is slowly becoming more known to consumers, as well as its uses. “We employ some of the industry’s most innovative tracking and carport solutions, which have been proven and deployed worldwide.

Both our PST-2AL (Dual-Axis) and PST-1AX6 (Single-Axis) trackers utilize Sun Action Trackers’ Real-Time Solar Sensing Technology. Our steel is made from a revolutionary product known as Magnesium Alloy Coated steel which will stand up to the rigors of the elements,” added Roman.

A dual-axis tracker uses independent systems that use two motors, moving in from East to West and North to South.

Roman explained, “Dual Axis Tracking Technology is independent systems that use two motors moving 42 to 24 modules (72 cell) in the East to West direction with rotating angles of +135 to -135 degrees and in the North to South direction with rotating angles of 0 to +60 degrees.

The Tracker uses patented real-time solar sensors, along with magnesium alloy coated steel to optimize energy production and the system is structurally rated to 105mph in stow.” Whereas single-axis tracking technology only uses one motor. “Single Axis Tracking Technology is a linked row system that uses one drive motor to moving 399 modules (72 cell) in the East to West direction with rotating angles of +45 to -45 degrees.

The Tracker uses patented real-time solar sensors, along with magnesium alloy coated steel to optimize energy production and the system is structurally rated to 110mph in stow.”

Solar tracking in Texas is beneficial to consumers seeking to receive an additional 25 to 45 percent of production while saving on the system-level costs.

Roman said, “The additional generation from the tracking systems also reduces the system-level costs for the same output, for example – the amount of racking, number of modules, and inverter sizing.”

The solar industry is helping to reduce our carbon footprint, saving consumers money on their utility bills, and following the sun to a brighter future.